FANUC System Alarm Codes List

Understanding Fanuc Alarms

Fanuc Alarms serve as warning signals that alert operators to the presence of a problem in the system. When an alarm goes off, it displays a specific code that indicates the cause of the issue.

Common Fanuc Alarms and Their Meanings

There are several Fanuc Alarms that an operator may encounter, and each code has a specific meaning. Faulty components or motherboard errors throw system alarms and put your machinery at a standstill. Consult the list below for common “900” FANUC system codes to get an idea of what’s causing your problem.

For further support, you’re in the best of hands with Tri Star CNC Services. Boasting decades of experience servicing critical CNC FANUC electronic components, we’ve got answers to all your questions. Give us a call for free nationwide phone support and we’ll help you get production back on track.

Contact Tri Star CNC Services for free phone technical support and troubleshooting.

| Alarm | Message | Description |

|---|---|---|

| ROM PARITY |

A parity error occurred in the CNC, macro, or servo ROM. Correct the contents of the flash ROM having the displayed number. |

|

| 910 |

SRAM PARITY : (BYTE 0) |

A RAM parity error occurred in the part program storage RAM. Clear the RAM, or replace the SRAM module or motherboard. Subsequently, re–set the parameters and all other data. |

| 911 |

SRAM PARITY : (BYTE 1) |

|

| 912 |

DRAM PARITY : (BYTE 0) |

A RAM parity error occurred in the DRAM module. Replace the DRAM module. |

| 913 |

DRAM PARITY : (BYTE 1) |

|

| 914 |

DRAM PARITY : (BYTE 2) |

|

| 915 |

DRAM PARITY : (BYTE 3) |

|

| 916 |

DRAM PARITY : (BYTE 4) |

|

| 917 |

DRAM PARITY : (BYTE 5) |

|

| 918 |

DRAM PARITY : (BYTE 6) |

|

| 919 |

DRAM PARITY : (BYTE 7) |

|

| 920 |

SERVO ALARM (1–4 AXIS) |

Servo amplifier alarm (first to fourth axis). A watchdog alarm condition occurred, or a RAM parity error occurred in the axis control card. Replace the axis control card. |

|

SERVO ALARM (5–8 AXIS) |

Servo amplifier alarm (fifth to eighth axis). A watchdog alarm condition occurred, or a RAM parity error occurred in the axis control card. Replace the axis control card. |

|

| 926 |

FSSB ALARM |

FSSB alarm. Replace the axis control card. |

| 930 |

CPU INTERRUPT |

CPU error (abnormal interrupt). The motherboard or CPU card may be faulty. |

|

SRAM ECC ERROR |

An error occurred in RAM for part program storage. Replace the master printed circuit board (SRAM module), perform all–clear operation, and set all parameters and other data again. |

|

|

PMC SYSTEM ALARM PCxxx YYYYYYYYYYYYYY |

An error occurred in the PMC. For details of PCxxx, see the list of system alarm messages in Section A.2, ”LIST OF ALARMS (PMC)” in this manual. |

|

|

PMC WATCH DOG ALARM |

An error occurred in the PMC. (Watchdog alarm) The motherboard may be faulty. |

|

|

NMI OCCURRED IN PMCLSI |

With the PMC–SA1, an error occurred in the PMC control LSI device on the motherboard. (I/O RAM parity) Replace the motherboard. |

|

|

NMI OCCURRED IN SLC |

With the PMC–SA1, an I/O Link disconnection was detected. Check the I/O Link. |

|

|

NMI OCCURRED IN OTHER MODULE |

An NMI occurred on a board other than the motherboard. The option board may be faulty. |

|

|

NON MASK INTERRUPT |

An NMI occurred as a result of an unknown cause. |

|

|

F–BUS ERROR |

A bus error occurred on the FANUC bus. The motherboard or option board may be faulty. |

|

|

BUS ERROR |

A bus error occurred on the motherboard. The motherboard may be faulty. |

|

|

L–BUS ERROR |

A bus error occurred on the local bus. The motherboard may be faulty. |

Contact Tri Star CNC for repairs

Troubleshooting Fanuc Alarms

When a Fanuc Alarm goes off, operators should take these steps to troubleshoot the problem as soon as possible:

-

Check the Alarm Code: The first step in troubleshooting any Fanuc Alarm is to check the code. This will provide valuable insight into the cause of the issue.

-

Refer to the Fanuc Manual: The Fanuc Manual is an excellent resource for troubleshooting any issues that may arise in the system. It provides detailed information on each alarm code and how to resolve it.

-

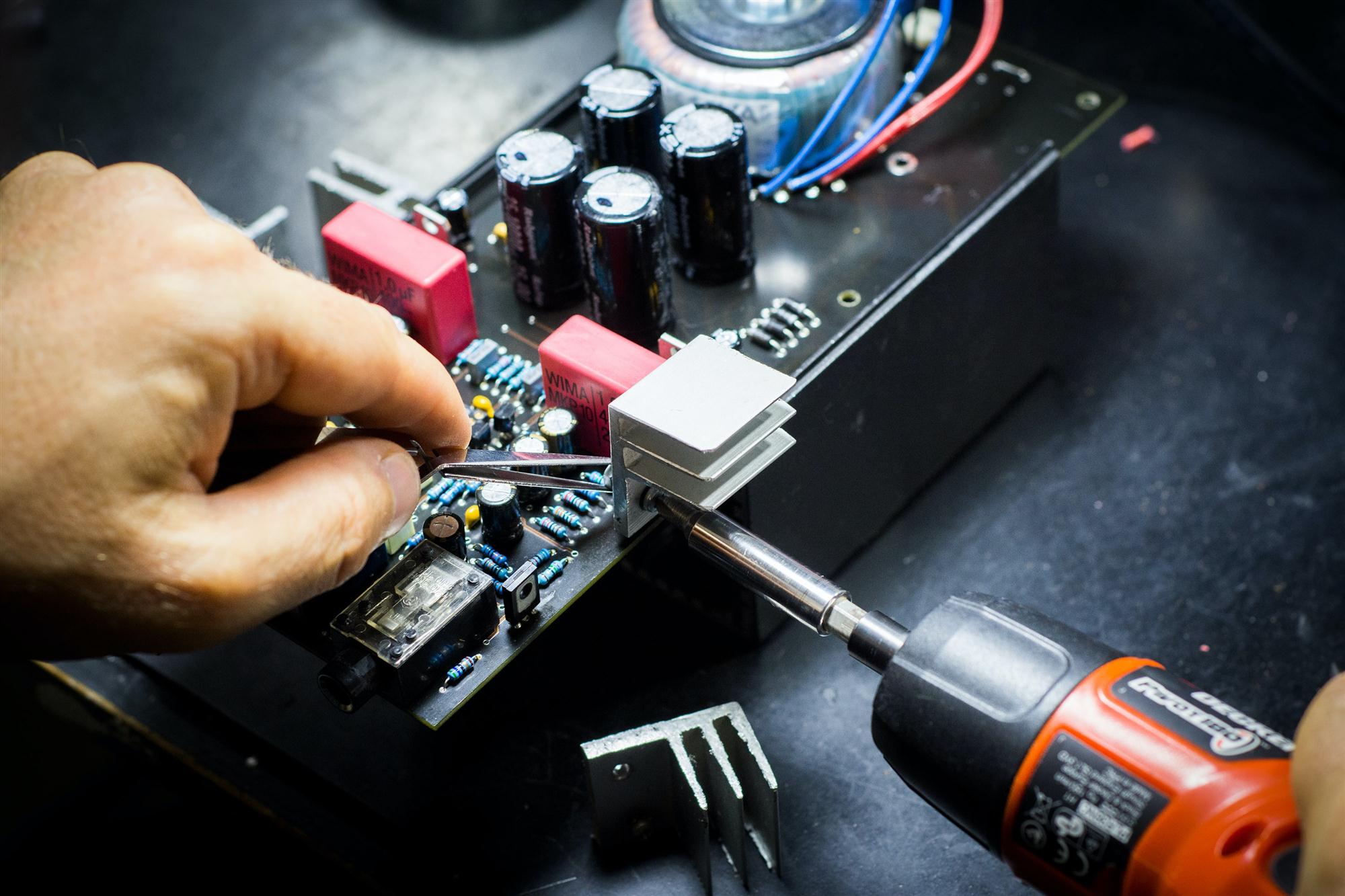

Check the Machine: Operators should also check the machine for any visible signs of damage or wear and tear. This could include loose wires, damaged components, or other issues.

- Contact Tri Star CNC for repairs & phone support